Welcome To Star Packaging Systems

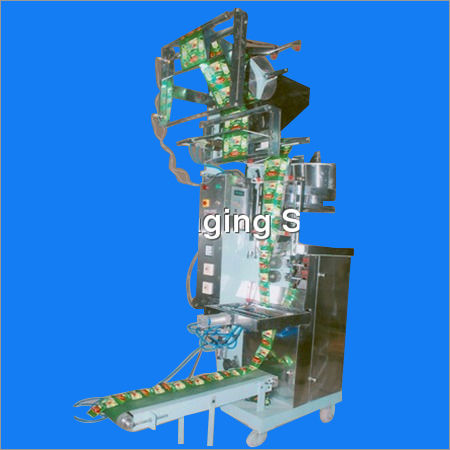

Mouth Freshener Packing Machine

50000.00 - 500000.00 INR/Unit

Product Details:

- Noise Level Less Than 70 dB

- Power Supply Single Phase

- Usage Industrial

- Application Pouch Packaging of Mouth Freshener

- Type Mouth Freshener Packing Machine

- Material Stainless Steel

- Computerized Yes

- Click to view more

X

Mouth Freshener Packing Machine Price And Quantity

- 50000.00 - 500000.00 INR/Unit

- 1 Unit

Mouth Freshener Packing Machine Product Specifications

- PLC Control

- Mouth Freshener Packing Machine

- Industrial

- Yes

- 220V

- Pouch Packaging of Mouth Freshener

- 2.5 kW

- 400 Kg

- Stainless Steel

- 1100 x 950 x 2100 mm

- Less Than 70 dB

- Electric

- Heat Sealing

- Silver & Blue

- Single Phase

- Automatic

Mouth Freshener Packing Machine Trade Information

- 1 Unit Per Week

- 1 Week

Product Description

We are affianced in manufacturing, exporting and supplying high quality Mouth Freshener Packing Machine that require low maintenance and can be installed easily. These machines are used in various industries for the packaging of spices and other edible items in pouches and are fabricated using premium quality components and advanced technology inline with the defined industry standards. The offered machines are available in various technical specifications to meet the diverse needs of the clients. We offer these Mouth Freshener Packing Machine at industry leading prices.

Products Features:

Products Features:

- High strength

- Sturdiness

- Smooth operation

- High performance

Specification:

| Type of seal | 3 side seal |

| Weight of packaged | 2gm. to 10gm. |

| Film Size | W-60mm. to 100mm. L -50mm. to 80mm. |

| Speed with a/c frequency cont. | 150 to 250 pouch/min. |

| Power consumption | 220vac. 50Hz. single phase Max. Load -2 kw |

| Film roll | laminated film in 3layer Min.thick.60mic |

| Machine dim. | 750x550x1785mm |

| Weight | Gross.wt.450kg. |

Advanced PLC Control System

The machine utilizes a sophisticated PLC control system, enabling operators to set parameters and monitor the packaging process with ease. This ensures consistent pouch sealing, minimal errors, and reduced operational downtime. The interface is user-friendly, making computerized adjustments fast and accurate, catering to various packaging needs.

Stainless Steel Build for Longevity

Built from robust stainless steel, the Mouth Freshener Packing Machine is engineered for durability and hygiene. Its corrosion-resistant materials meet industrial standards, making it suitable for prolonged use in demanding environments. The sleek silver and blue finish not only adds aesthetic value, but also allows for easy cleaning and maintenance.

Low Noise and Energy Efficient Operation

Operating at under 70 dB, this packing machine keeps noise disturbances minimal, contributing to a more comfortable work atmosphere. With its 2.5 kW power usage and 220V single-phase supply, it is both energy-efficient and cost-effective, meeting the needs of modern industrial settings.

FAQs of Mouth Freshener Packing Machine:

Q: How does the Mouth Freshener Packing Machine ensure consistent sealing quality?

A: The machine employs a PLC-controlled heat sealing system that precisely regulates temperature and pressure during the sealing process. This computerized control delivers uniform seals on every pouch, reducing wastage and maintaining product freshness.Q: What benefits does computerized operation provide for this automatic packing machine?

A: Computerized operation via the PLC system offers quick parameter adjustments, error detection, and process monitoring. This increases productivity, minimizes manual intervention, and guarantees reliable, high-quality pouch packaging every time.Q: Where is this packing machine typically used within the industry?

A: This automatic mouth freshener packing machine is widely utilized in food processing plants, packaging units, and industrial setups across India. Its suitable for exporters, manufacturers, and suppliers who require fast, accurate, and hygienic pouch packaging solutions.Q: What is the overall process for packaging mouth fresheners with this machine?

A: Operators load mouth freshener products into the hopper, configure settings through the PLC interface, and start the machine. The product is automatically dispensed into pouches, heat-sealed, and then precisely cut, producing uniform, ready-to-distribute packs.Q: When should you consider using an automatic mouth freshener packing machine?

A: You should opt for this machine when you need high-speed, consistent, and hygienic packing of mouth fresheners for industrial-scale production, especially when manual packing becomes inefficient or causes quality inconsistencies.Q: How does the stainless steel construction enhance the machines usability?

A: Stainless steel construction ensures longevity and resistance to corrosion, which is vital for maintaining hygiene standards in food packaging. It also simplifies cleaning procedures, making the machine more user-friendly and reliable over time.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email